Tampone per stampa tampografica WINNEO

Caratteristiche di questo prodotto:

Stampa di trasferimento precisa

La superficie è fine, in grado di assorbire accuratamente l'inchiostro e trasferirlo completamente sul pezzo, garantendo motivi nitidi.

Ampia adattabilità

Può essere personalizzato in diverse forme e dimensioni, adatto a pezzi curvi e di forma speciale, soddisfacendo varie esigenze di stampa.

Testa in gomma antistatica opzionale

Bassa resistenza superficiale, che riduce l'assorbimento della polvere ed evita difetti del modello causati dall'elettricità statica durante la stampa.

Resistenza alla corrosione dei solventi

Resiste a vari solventi per inchiostro, non si gonfia o indurisce facilmente e si adatta ad ambienti di stampa complessi.

WINNEO Tampografia Tampone

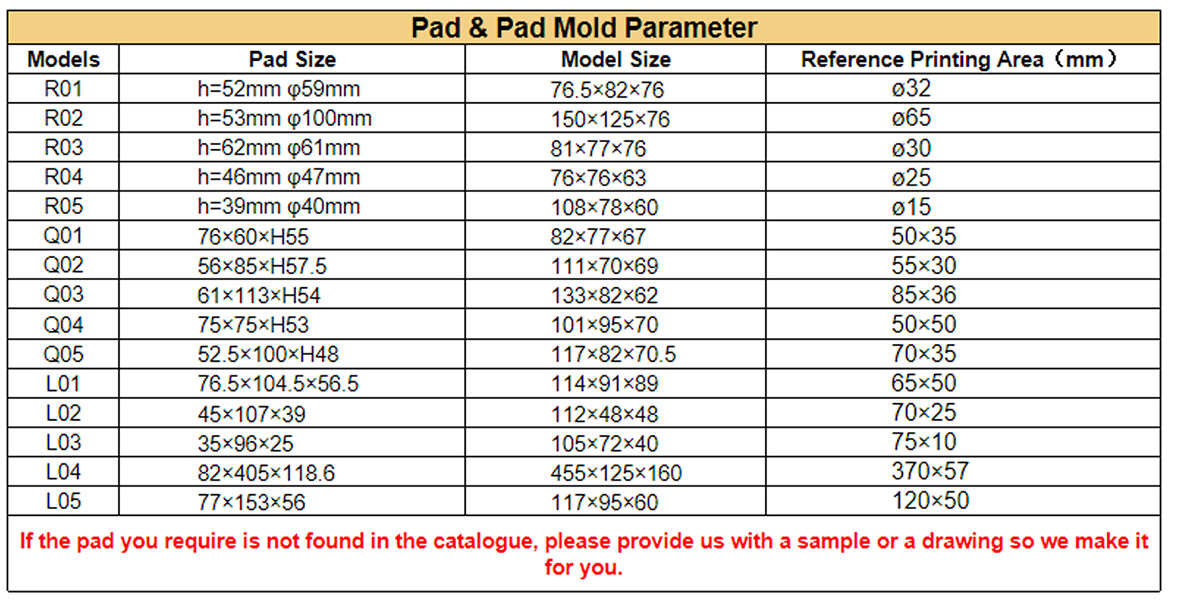

WINNEO Tampone per stampa a tampone Parametro

Preoccupazioni dei clienti

Breve durata di vita: Il tampone di stampa è soggetto a crepe, scheggiature e degrado elastico, richiedendo sostituzioni frequenti che ritardano la produzione e aumentano i costi.

Scarso effetto di stampa: Il tampone di stampa presenta bolle/fori, una superficie irregolare o una durezza inadeguata, che causano carenza di inchiostro, sfocature e motivi distorti sui prodotti stampati, con conseguente scarto del prodotto.

Generazione di elettricità statica: Il tampone di stampa non è trattato antistatico e tende ad accumulare elettricità statica, che potrebbe danneggiare i componenti elettronici o attirare la polvere contaminando i prodotti stampati.

WINNEO Standard di Tampone per stampa a tampone

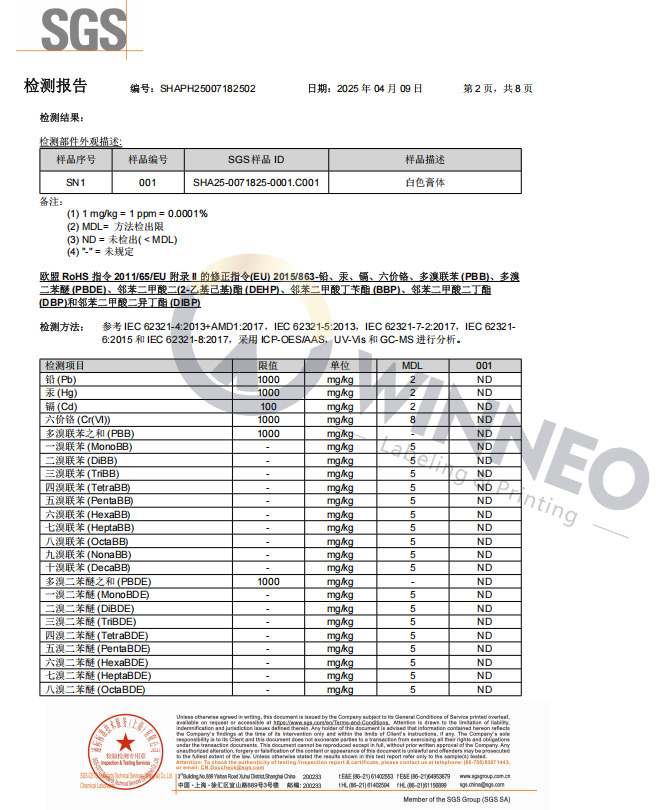

WINNEO Tampone per stampa tampografica Materia prima Ccomponente Standard

Questo è il rapporto originale dei test di composizione per le materie prime utilizzate nel tampone per stampa tampografica WINNEO. Questo rapporto dimostra che le materie prime utilizzate nel nostro tampone per stampa tampografica soddisfano gli standard qualitativi. Materie prime qualificate garantiscono che la successiva produzione del tampone sia conforme agli standard pertinenti.

Pulisci lo stampo del tampone per stampa a tampone

Il dosaggio preciso garantisce la qualità del tampone per stampa tampografica

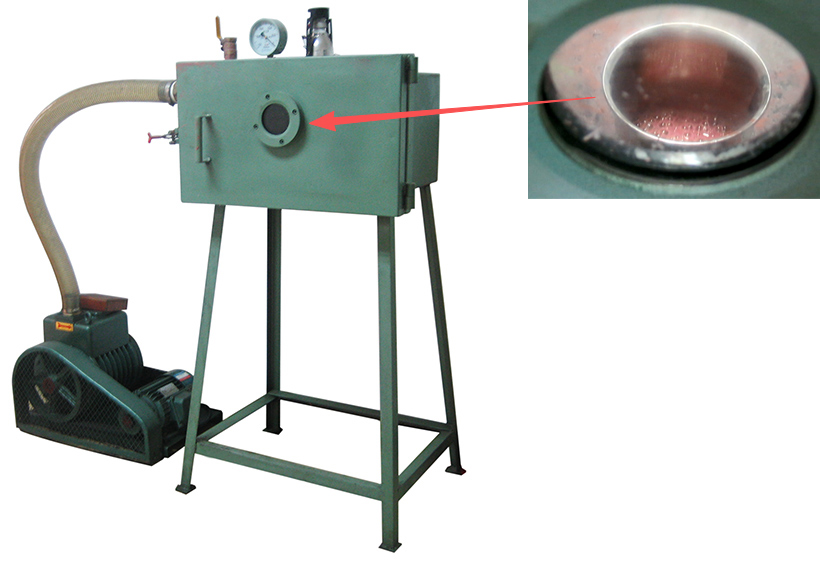

Aspirare la soluzione preparata per evitare fori nel tampone per stampa a tampone

WINNEO QC Standard

Standard di imballaggio WINNEO

Standard post-vendita WINNEO

Risposta efficiente entro 24 ore, con personale dedicato assegnato al follow-up. Supporto tecnico online personalizzato a vita.

I clienti consigliano

I tamponi per stampa tampografica WINNEO sono molto apprezzati dai clienti.

Domande frequenti

1. Perché il tampone per stampa tampografica non assorbe l'inchiostro?

Principalmente perché la durezza è troppo elevata e impedisce il contatto completo con la lastra di stampa per assorbire l'inchiostro; può anche darsi che macchie d'olio o impurità sulla superficie ostacolino l'adesione dell'inchiostro.

2. Perché i motivi stampati non sono chiari?

Durezza inadeguata (tamponi rigidi per motivi fini), superficie irregolare o danneggiata, che determina un assorbimento/trasferimento non uniforme dell'inchiostro.

3. Perché il tampone per stampa tampografica non è durevole?

Il silicone contiene impurità, un eccesso di olio di silicone danneggia la struttura o le dimensioni non corrispondono al motivo (per motivi più grandi utilizzare un tampone piccolo), rendendolo soggetto a crepe e invecchiamento.

4. Perché ci sono bolle nella stampa?

Una forma troppo piatta, una curvatura errata o il punto centrale che si allinea direttamente con il motivo, causando l'intrappolamento dell'aria; anche danni alla superficie possono causare questo problema.

Tempo di lavoro

Ricevi le tue informazioni 24 ore su 24

Ora di Pechino: Dal lunedì al venerdì 9:00-17:30