Sep 11, 2025

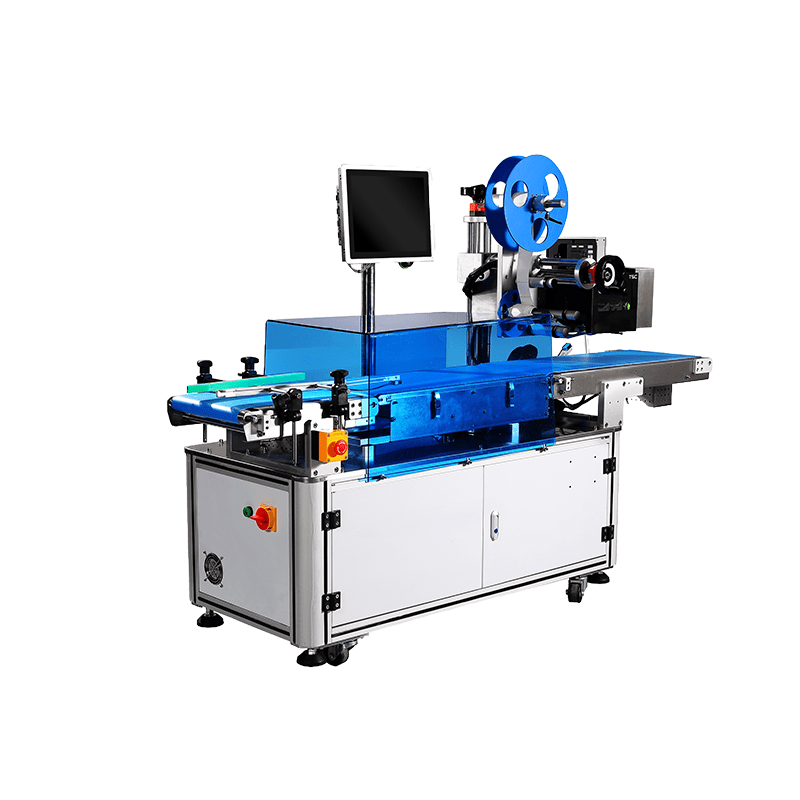

Automazione e esigenze dell'industriaNella produzione moderna, molte aziende si rivolgono a un Etichettatrice completamente automatica per ottimizzare la produzione e migliorare la velocità di etichettatura. Queste macchine eccellono nell'applicazione di etichette in modo uniforme e rapido, rendendole adatte a operazioni ad alto volume. Tuttavia, la sola automazione non garantisce la piena conformità a tutti gli standard normativi e qualitativi. Sebbene un'etichettatrice completamente automatica offra un'applicazione delle etichette ad alta velocità ed efficiente, non verifica il peso di ogni confezione. In settori come quello alimentare, questo può portare alla fuoriuscita di prodotti sottoriempiti o sovrappeso, con conseguenti rischi di conformità e potenziali richiami. Al contrario, un'etichettatrice con unità di pesatura integrata garantisce che ogni articolo soddisfi sia gli standard di etichettatura che quelli di peso, offrendo un ulteriore livello di controllo qualità e tutela normativa. A Etichettatrice con unità di pesatura risolve queste sfide combinando due funzioni critiche in un unico sistema: applicazione di etichette di precisione e verifica del peso in tempo reale. Questo duplice approccio non solo riduce gli errori, ma garantisce anche la conformità agli standard globali. Perché la conformità e l'accuratezza sono fondamentali Cibo e bevandeLe confezioni non riempite correttamente comportano multe e perdita di fiducia da parte dei consumatori.I prodotti eccessivamente pieni incidono sui margini di profitto di migliaia di unità. Per le industrie alimentari, un'etichettatrice con unità di pesatura garantisce sia protezione che efficienza. Caratteristiche principali dell'etichettatrice con unità di pesaturaA differenza di altri tipi di macchine etichettatrici, questo modello aggiunge un modulo di pesatura per ispezionare ogni articolo.Velocità: 80–150 etichette al minuto.Precisione: ±0,5 mm nel posizionamento dell'etichetta.Monitoraggio del peso: rifiuta immediatamente le unità fuori specifica.Connettività dei dati: sincronizzazione con ERP e sistemi di qualità per la tracciabilità.Pronto per la conformità: conforme alle direttive FDA, ISO e UE in materia di imballaggio. CaratteristicaValore / BeneficioVelocità80–150 etichette/minPrecisione dell'etichetta±0,5 millimetriVerifica del pesoControlli di superamento/fallimento in tempo realeIntegrazioneSistemi ERP e di gestione della qualitàMigliori applicazionicibo Casi di studio Esempio di produttore alimentareUn produttore europeo di snack è stato penalizzato per confezioni sottopeso. Con la pesatura integrata nell'etichettatura:I richiami sono diminuiti del 15% nel primo anno.Il risparmio annuo ha superato i 120.000 € grazie alla riduzione delle multe.Le lamentele dei consumatori relative al peso non uniforme degli imballaggi sono diminuite drasticamente. ROI e impatto aziendaleSebbene l'investimento iniziale sia più elevato rispetto a un modello solo feeder, il ritorno sull'investimento (ROI) è interessante se si considerano i costi di conformità. MetricoPrima dell'integrazioneDopo l'integrazioneRisparmioRichiami all'anno20–150–80%Costo di richiamo annuale1.000.000 di dollari$200.000800.000 dollariErrori di etichettatura (unità/anno)20.0004.00080% La maggior parte dei produttori recupera l'investimento in 12-18 mesi grazie a multe ridotte, meno richiami e tassi di errore più bassi. Oltre la conformità: vantaggi aggiuntiviPrevenzione degli errori: i prodotti difettosi vengono scartati prima di lasciare la linea.Efficienza: l'etichettatura e la pesatura combinate in un unico processo consentono di risparmiare tempo.Tracciabilità: dati relativi a peso ed etichetta memorizzati per audit e reporting.Fiducia del cliente: un imballaggio accurato aumenta l'affidabilità del marchio. Come realizzare una macchina etichettatrice ad alta efficienza per le PMIUn'etichettatrice con unità di pesatura è più di un semplice upgrade: è una garanzia per i settori in cui gli errori di conformità possono essere catastrofici. Combinando la precisione delle etichette con la verifica del peso, protegge i produttori da costosi richiami, supporta la conformità normativa e rafforza la fiducia dei clienti. Nel settore alimentare, questo sistema garantisce che ogni pacco spedito sia accurato, coerente e pronto per la verifica.

PER SAPERNE DI PIÙ